Technical leadership is built with innovation

Finnchain is known for its continuous product development. After over 30 years of manufacturing chain scraper systems, we have managed to take our product’s durability and service life to the next level.

PRODUCT DEVELOPMENT WITH

Patented technology

PRODUCT DEVELOPMENT

Finnchain Oy designs, manufactures and installs top-quality sludge scraper systems for water and wastewater treatment processes. We offer a reliable, low-maintenance system, comprising of the latest technology in the field.

We develop our product continuously in order to deliver on our promise of quality. The several international patents granted for our innovations and our success in the global market are a testament to our successful product development. In 2008, the President of Finland rewarded Finnchain Oy the INNOSUOMI award as a recognition of our innovative work and our efforts to improve the company’s competitiveness.

Scraper innovations for rectangular tanks

PATENTED COLLECTOR CHAIN

WIDE BEARING SURFACE AREA GUARANTEES LONG SERVICE LIFE

TRADITIONAL MODEL:The cog and the chain share | FINNCHAIN SOLUTION: The driving wheel is in contact with the entire |

Chain models

COLLECTOR CHAIN

|

COLLECTOR CHAIN

|

DOUBLE CHAIN

|

PATENTED DRIVE WHEEL

ADJUSTABLE-PITCH DRIVE WHEEL

PATENTED CHAIN WATCH

PATENTED CHAIN WATCH

PATENTED SCRAPER FLIGHTS

CLOSED PROFILE MAKES SCRAPER FLIGHTS STRONG AND DURABLE

| Scraper flight | Height, mm | Momentiaof inertia, mm4 | Torsional moment, mm4 | |

|

FC-190 | 190 | X – X : 3 605 000 Y – Y : 376 100 | 479 313 |

|

FC-200 | 200 | X – X : 5 724 000 Y – Y : 1 152 500 | 2 520 000 |

|

FC-220 | 220 | X – X : 10 881 245 Y – Y : 5 083 635 | 7 012 345 |

|

FC-300 | 300 | X – X : 11 183 000 Y – Y : 1 664 100 | 2 521 000 |

|

FC-310 | 310 | X – X : 19 917 118 Y – Y : 5 600 130 | 7 013 038 |

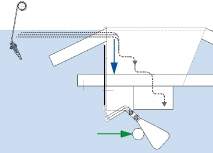

PATENTED FinnFlow

OPERATING PRINCIPLE

The intelligent FinnFlow® system takes advantage of natural water flow to create a reliable, energy-saving and low maintenance system. The system suits all tanks requiring surface scum removal. The requirement is that the FinnFlow® collector can be connected to a removal pipe or a channel for cleaned water in order to generate a flow.

The most common applications of the FinnFlow® system are preliminary and secondary sedimentation tanks in which scraper flights transfer the sludge close to the FinnFlow® collector. The FinnFlow® system collects surface scum to the collector by regulating the water levels. Since it uses a continuous flow, treated clean water comes along with the surface scum.

The system’s intelligent technology directs surface scum to a smaller scum collection box located inside the collector, while transferring the treated water to a removal pipe for clean water via a pipe located at the bottom of the collector. Water movement is regulated at each stage at different water levels.

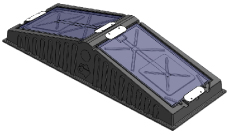

SOLAR-COVERS

PREVENT THE ODOR DISORDER

Finnchain Solar Covers are designed to prevent odors from the tank. For this reason, the roof modules are connected closely and if necessary, activated charcoal filters can be used for deaeration. At the same time this also prevents harmful gases from entering the environment.

FC-SOL-1500 cover |

FC-SOL 1500 cover with solar panels |

|

|

|

|

RENEWABLE ENERGY

Finnchain’s Solar Covers also allow use of renewable energy, as cover modules can be equipped with solar panels.

The surface area of the tank can then be utilized for renewable energy utilization.

Since covers prevent sunlight from entering the water, amount of algae is decreasing. Covers also prevent snow, rain or sand dust entering the tank.

Scraper innovations for circular tanks

CORROSION RESISTANT MATERIALS

CORROSION RESISTANCE AND ENERGY EFFICIENCY WITH SMART MATERIAL CHOICES

TEST TANK

OWN TEST TANK FOR PRODUCT DEVELOPMENT

Finnchain constantly develops its products. Product development requires frequent product testing, which is why we built our own test tank, 25 metres in diameter. During this extensive product development process, we have upgraded our scraper structurally and discovered the best possible raw material compositions for different components. We have upgraded almost all of our components during the process. Our greatest innovations include the patented conveyor chain and driving wheel systems, new idle wheels and tightening shafts, lighter surface sludge scraper, more efficient surface sludge removal, self-steering bottom scraper wheels and the use of two motors in large tanks.

PATENTED CONIC PIN

SPECIAL STRUCTURE PREVENTS CHAIN BENDING

PATENTED SURFACE SCUM REMOVAL

SURFACE SCUM REMOVAL

The scraper flight in the Finnchain system, moving at the surface of the tank, transfers the floating scum to the scum collection box on the side wall of the tank. The efficiency of the scum removal is based on scum gates located in the scum collection box. The scum gates open up when the scraper flight approaches the scum collection box, causing a water flow which enables the efficient collection of the scum. The water flow transfers the surface scum to a removal pipe for further treatment, and prevents freezing during winter. The opening of the scum gates can be adjusted, which enables more efficient removal of the surface scum.

”For decades, Finnchain’s strong expertise and continuous development work has produced innovative and patented solutions for water and wastewater treatment all around the world.”

Would you like to know more?

Contact us or find yourlocal representative